During 2019 China Brake Annual Conference, TecSA staff has presented the most recent technological developments in brake testing rigs.

The new vector speed AC motor highly improves the limitations of traditional stands, whose technological specifications date back to the ‘70s.

Traditional AC motors, in fact, allow only to perform the conformity of production tests for brake pads at constant speed of 660 rpm, to meet the legal requirements of European standard ECE-R90 Annex 9 and the Chinese standards GB/T 34007-2017 and GB5763-2018.

New Friction Quality Test machines present the possibility to run a wider range of tests with a single equipment:

- Drag tests at 660 rpm, for full scale pads (motorbikes, go-karts and passenger cars) and reduced scale pads (light commercial vehicles and heavy commercial vehicles);

- Dynamic tests (performance tests, such as AK Master according to SAE J2522 and ISO 26867), through variable speed option and inertia simulated by the software. FQT can work as a full-scale dynamometer bench for a wide range of brake systems, from bicycles to mid-sized passenger cars;

- Bedding of brake systems.

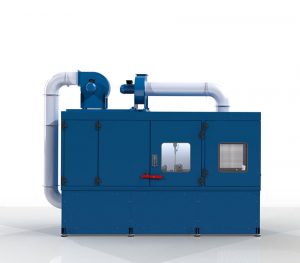

TecSA product-line includes two models of FQT:

- FQT 1200: max speed 1500 rpm, inertia range 1-30 kgm², max braking moment 1500 Nm

- FQT 2000: max speed 2000 rpm, inertia range 1-60 kgm², max braking moment 2000 Nm.

FQTs are provided with TecSA software, that is completely open and user-friendly, with spare parts freely available on the market and with modular layout, to reduce installation times and costs.